What Is The Difference Between Power Float and Floor Hardener Concrete Slab?

Specifications

Quotation

Free Quotation To You !

Checklist

To Understand Your Need !

Budget

To Understand Your Budget !

Details

Why Floor Hardeners Make Power Floated Concrete Superior: Malaysian Expert Guide

HIN CONSTRUCTION

Understanding the Role of Floor Hardeners in Concrete Finishing

Image Source: Sika Group

Floor hardeners are vital components that create durable and high-performing concrete floors. They solve common problems with untreated concrete like dusting, abrasion, and moisture absorption by creating a stronger surface layer. Anyone working on industrial flooring projects needs to know these materials and how to apply them properly.

What is a ?

concrete floor hardener

A concrete floor hardener makes concrete surfaces more durable and better performing. You'll find two main types: dry shake hardeners and liquid hardeners. Dry shake floor hardeners are factory-blended powders that contain special aggregates, cement, and additives that boost workability [1]. Workers apply these to fresh concrete to create a single unified floor system [2].Dry shake hardeners fall into three simple categories based on their aggregate type:

- Natural quartz aggregate

- Synthetic (non-metallic) mineral aggregates

- Metallic and metallic alloy aggregates [3]

How dry shake floor hardeners are applied

The application of dry shake floor hardeners follows a systematic process that starts with good surface preparation. The concrete needs proper placement, unification, and leveling to the right grade [4]. A bull float then compacts and unites the concrete surface [4].Workers spread about two-thirds of mineral-aggregate hardeners evenly on the fresh concrete surface before any bleed water shows up [4]. The hardener should get slightly darker from moisture before workers embed it with a wood bull float or modified highway straightedge [4]. The remaining third goes on at right angles to the first application [4].

Metallic and colored dry shake hardeners need a different approach. Workers spread these after the bleed water disappears, right when the concrete loses its surface shine.

Why timing matters during application

Timing is the key to successful floor hardener application. The concrete must reach just the right stage—not too wet or dry—before applying the hardener. Early application leads to too much bleed water, which causes discoloration and weaker surfaces [6].Late application means the hardener won't merge properly with the base concrete, which could cause delamination or scaling [6]. Temperature, humidity, and wind affect this timing because they change how fast concrete sets [7]. Applying too soon might hurt durability and require more hardener [7].

Contractors should watch the concrete surface carefully. The best time to apply is when it can support foot traffic with minimal marks, usually 7-14 days after pouring [6].

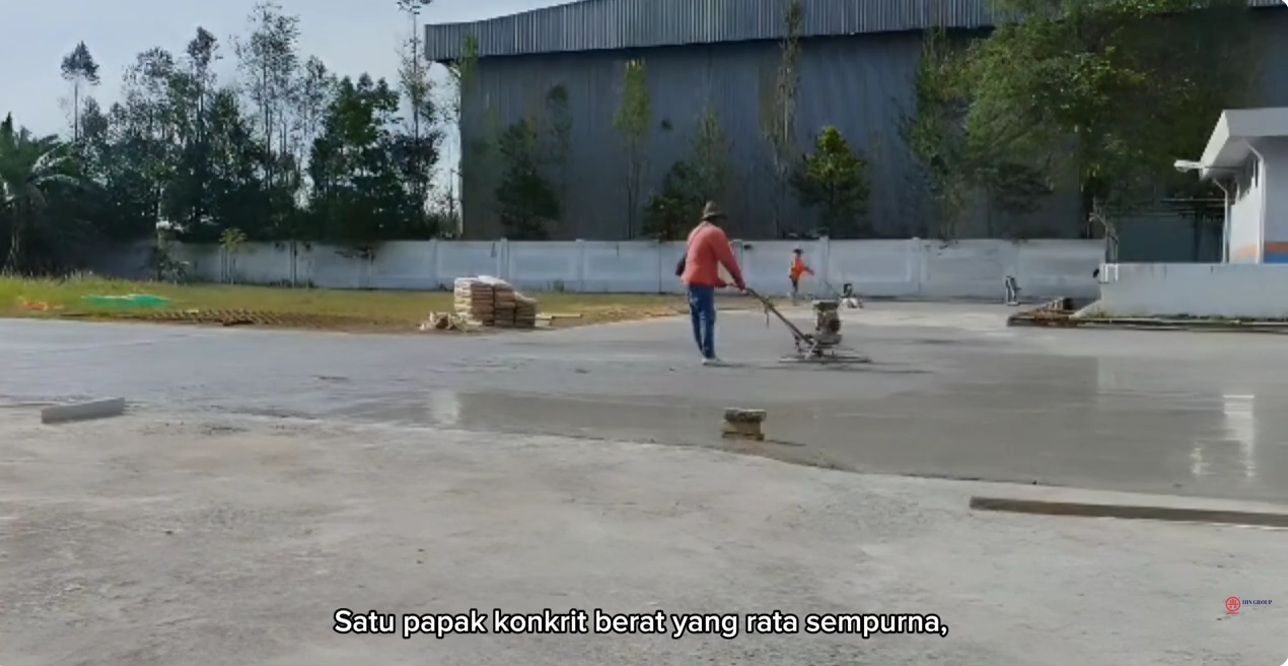

Comparing Power Floated Concrete With and Without Hardeners

Image Source:

The Best Concrete Slab Powerfloat Driveway Construction Contractor In Slangor | KL

Power floated concrete floors work great on their own, but floor hardeners make them even better. These two approaches lead to different results when it comes to durability, maintenance needs, and looks.

Surface strength and wear resistance differences

Power floated concrete with dry shake floor hardeners shows much better than standard power floated surfaces. Test results prove that floors treated with hardeners are 200% more resistant to abrasion than plain concrete abrasion resistance. This is a big deal as it means that floors with hardeners reach compressive strength values over 60 MPa [8], making them tougher against heavy traffic and impact damage.The hardened floors also resist liquid penetration better. When the hardener reacts with free calcium carbonate in the concrete, it creates a dense surface layer that seals the pores and limits how much moisture gets absorbed.

Dusting and maintenance implications

might be smooth, but they can still create dust—loose powder that forms when the surface breaks down Power floated concrete surfaces[10]. This happens because the wearing surface isn't as strong as hardened versions.Dry shake hardeners solve this dusting problem. The hardener goes into the concrete's top layer and creates a denser surface that stops fine dust particles from forming under traffic.

The maintenance needs are quite different too. Hardened floors need minimal care, while untreated power floated surfaces often require regular cleaning and occasional resealing to stay in good shape.

Visual finish and texture comparison

Hardened and non-hardened power floated floors look quite different from each other. Regular power floated concrete has a smooth but somewhat porous finish, and you might see swirl marks from the floating process [12]. These floors usually look matte or slightly textured.Floors with dry shake hardeners look more polished and attractive. You can burnish them until they shine, and they come in different colors by adding pigments [3]. The surface looks more even, with a finer texture and better light reflection—features that retail and commercial spaces really value.

Performance Benefits of Using Floor Hardeners in Power Float Applications

Image Source: The Best Powerfloat Concrete Slab For Factory | Manufacturer In Malaysia

Measurable performance benefits show up when floor hardeners become part of power floated concrete applications. These specialized treatments revolutionize ordinary concrete into that withstand extreme conditions. industrial-grade surfaces

Improved abrasion resistance in high-traffic zones

Floor hardeners substantially improve abrasion resistance—knowing how to withstand rubbing, rolling, sliding, cutting and impact forces [13]. High-traffic environments like manufacturing facilities and distribution centers need this property. Abrasion testing standards show properly hardened floors can achieve classification AR2, the usual minimum requirement for industrial floors.Metallic dry shake hardeners deliver exceptional performance and create a dense, tough surface that withstands abrasion and impact loading in many industrial environments.

Resistance to oil, grease, and chemical spills

Raw concrete absorbs liquids because of its porous nature. Floor hardeners close these pores and create a barrier that repels contaminants. These treatments reduce dusting while preventing oil, grease, and chemical penetration. Automotive workshops, chemical processing facilities and food production plants need this feature as spills happen often. Since oils destroy concrete's strength properties, hardeners provide crucial protection.Longer lifespan and reduced repair frequency

The most compelling economic benefit lies in how floor hardeners extend service life. Hardened surfaces cut maintenance costs and minimize plant shutdowns from floor repairs. Properly treated floors deliver cost savings both now and later. Surfaces with floor hardeners become virtually dust-free and create cleaner environments that need less cleaning and maintenance. The extended durability stretches replacement cycles substantially, which produces higher returns on the original investment.Choosing the Right Floor Hardener in Malaysia

Image Source: Builds With Confident Of Floor Slab Powerfloat In Selangor Klang Now

Malaysian construction projects need careful selection of floor hardeners based on local product options and project needs. The country's unique climate and building practices make this process different from standard selection methods.

Types of floor hardeners available locally

Malaysian suppliers stock several types of floor hardeners for different uses. Non-metallic floor hardeners such as MASTERPAV NM200 are accessible to more people. These work well both indoors and outdoors where better wear resistance matters. You'll find these products in 25kg bags that cover 5-6kg per square meter.Metallic floor hardeners are also available for heavy-duty industrial needs. Malaysian suppliers provide these hardeners in several colors including natural, silver gray, oyster gray, cherry red, terracotta, and summer green. This color range lets designers add corporate colors or create zone markers without extra painting.

Factors to consider: traffic load, environment, budget

Traffic load review [link_1] plays a key role in picking the right floor hardener. Light forklift traffic or moderate abrasion needs about 3kg/m², while heavy forklift areas need 5-7kg/m² [3].Malaysia's humid tropical weather creates special challenges. High heat can speed up drying, but too much humidity slows down curing. These weather conditions affect which hardener works best and when to apply it.

The full picture must include both upfront costs and long-term value. Liquid hardeners cost less at first, but dry shake hardeners last longer and need less maintenance over time [20].

Common mistakes in selecting floor hardeners

The biggest problem comes from picking hardeners that don't match actual building conditions [21]. People often misread product features, which leads to early failure.There's another reason things go wrong - applicators mix up weight and volume measurements during partial mixing. Different densities between activators and hardeners mean wrong ratios and poor curing [22].

Projects often overlook concrete mix compatibility. The concrete's must be at least 0.50 to get enough water for proper hardener hydration water-cement ratio. Missing this basic requirement often causes poor bonding and surface problems.

Conclusion

Conclusion

Floor hardeners change ordinary power floated concrete into superior industrial surfaces that last longer and perform better. This piece shows how these specialized materials create monolithic floor systems that can handle extreme conditions and need less maintenance.The results speak for themselves. Hardened floors work better than standard power floated surfaces in every way. Tests show floors with hardeners are 200% more resistant to abrasion and reach compressive strength values that exceed 60 MPa. This means they last longer and save money over time.

The right application makes all the difference. The hardener bonds well with the base layer only when concrete hits the perfect moisture level. That's why contractors must watch both weather conditions and how fast concrete sets to get the best results.

Malaysian builders deal with special challenges because of our tropical weather. High humidity changes how concrete cures, and heat can dry it too fast. These factors mean builders need special expertise to pick and apply floor hardeners right. The market has non-metallic, metallic, and colored options to fit different project needs.

Understanding traffic load is vital when choosing hardeners. Light forklift areas might work fine with 3kg/m², but heavy industrial spaces just need 5-7kg/m² to stay protected. The concrete mix design must also match well because the water-cement ratio helps the hardener work properly.

Floor hardeners prove their worth quickly. They create better-looking surfaces that resist dust, oils, chemicals, and wear. The original cost pays off fast through lower maintenance costs, fewer fixes, and floors that last much longer. Malaysian industrial facilities looking for tough, high-performance flooring will find hardened power floated concrete is the best choice.

Key Takeaways

Floor hardeners transform ordinary power floated concrete into industrial-grade surfaces with superior durability and performance characteristics.• Floor hardeners increase abrasion resistance by 200% and achieve compressive strength exceeding 60 MPa compared to untreated concrete

• Proper timing during application is critical - hardeners must be applied when concrete can support foot traffic with minimal imprint

• Hardened floors eliminate dusting problems and resist oil, grease, and chemical penetration through dense surface sealing

• Traffic load assessment determines application rates: 3kg/m² for light use, 5-7kg/m² for heavy industrial environments

• Initial investment pays dividends through reduced maintenance costs, fewer repairs, and significantly extended floor lifespans

The key to success lies in understanding that floor hardeners create monolithic systems that bond with the base concrete, not just surface coatings.

Malaysian contractors must consider the tropical climate's impact on curing times and select appropriate hardener types based on specific project requirements and environmental conditions.

FAQs

Q1. What are the main advantages of using floor hardeners on power floated concrete?Floor hardeners significantly enhance the durability and performance of power floated concrete. They increase abrasion resistance by 200%, achieve higher compressive strength, reduce dusting, and improve resistance to oil, grease, and chemical spills. This results in longer-lasting floors with reduced maintenance requirements.

Q2. How does the application timing of floor hardeners affect their performance?

Timing is crucial when applying floor hardeners. They must be applied when the concrete can support foot traffic with minimal imprint, typically 7-14 days after pouring. Applying too early can lead to discoloration and weakening, while applying too late may result in poor integration and potential delamination.

Q3. What factors should be considered when choosing a floor hardener in Malaysia?

When selecting a floor hardener in Malaysia, consider the expected traffic load, environmental conditions, and budget. The humid tropical climate affects curing times, so choose products suitable for local conditions. Also, ensure compatibility with the concrete mix design and assess both initial costs and long-term value.

Q4. How do floor hardeners impact maintenance requirements for concrete floors?

Floor hardeners significantly reduce maintenance needs for concrete floors. They create a denser surface that eliminates dusting, resists liquid penetration, and withstands wear and tear better than untreated surfaces. This results in cleaner environments, less frequent cleaning, and fewer repairs over the floor's lifespan.

Q5. What are the different types of floor hardeners available, and how do they differ?

There are primarily two types of floor hardeners: dry shake hardeners and liquid hardeners. Dry shake hardeners come in non-metallic, metallic, and colored varieties. They offer superior durability and are available in various colors. Liquid hardeners are easier to apply but may not provide the same level of wear resistance as dry shake hardeners.

Top Concrete Driveway Contractor in Malaysia (Trusted by Industrial Owners)

Malaysia’s rapid industrial growth demands durable, high-load concrete driveway solutions — not shortcuts, not patchwork, and not inexperienced contractors.If you are searching for a reliable concrete driveway contractor in Malaysia, you are in the right place.

We specialise in industrial-grade concrete driveway construction, repair, and replacement for factories, warehouses, logistics hubs, commercial buildings, and high-traffic properties across Kuala Lumpur, Selangor, Klang, Shah Alam, Bangi, Kajang, and Semenyih.

Our team understands one thing clearly:

👉 A weak driveway disrupts operations. A strong driveway protects your business.

That is why every project is engineered to handle:

- Heavy lorries & container trucks

- Constant forklift movement

- Oil, water & chemical exposure

- Long-term wear without cracking or sinking

Our Core Concrete Driveway Services

- Concrete driveway construction (new & upgrade)

- Driveway repair & resurfacing

- Cracked, sunken & damaged driveway replacement

- Industrial parking & loading bay slabs

- Drainage correction & water flow solutions

- Asphalt removal & conversion to concrete

We design load-ready, long-life driveway systems that reduce maintenance, downtime, and future repair costs.

Why Industrial & Commercial Owners Choose Us

✔ Experienced in factory & high-traffic environments✔ Proper base preparation & reinforcement (not shortcuts)

✔ Clean site management & clear project scheduling

✔ Honest technical advice (even if it costs us the job)

✔ Local Malaysian team – fast response, real accountability

Planning to Repair or Build a Concrete Driveway?

Delaying the right solution often leads to:- Repeated patching costs

- Vehicle damage

- Safety risks

- Business disruption

👉 Click the WhatsApp button now to get a professional assessment and quotation within 24 hours.

Or Whatsapp us directly: 016-219 3181

Your driveway supports your business.

Make sure it’s built by people who understand that.

Areas We Serve

Concrete Driveway Contractor in:- Kuala Lumpur

- Selangor

- Klang

- Shah Alam

- Bangi

- Kajang

- Semenyih

- Cyberjaya

- Putrajaya

- Sepang

- Bangi Lama

- Sungai Chua, Kajang

- Ijok

It is the foundation of your logistics, safety, and daily operations.

When it fails, trucks stop. Work slows. Costs rise.

That is why serious factory and property owners in Malaysia choose a contractor who understands load, drainage, soil condition, and long-term durability – not just surface appearance.

If you want a driveway that lasts, supports heavy traffic, and protects your operations for years, speak to us.

👉 Click the WhatsApp button now for a professional assessment & quotation within 72 hours.

View more about What Is The Difference Between Power Float and Floor Hardener Concrete Slab? on main site